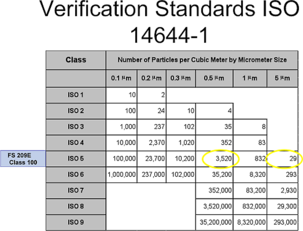

MedicCleanAir® Units are able to create a clean air environment of ISO 8 (class D), ISO 7 (class C), and sometimes even ISO 6 level in relation to isolation qualifications

Depending on the type of room (for infectious patients, for immune-compromised patients, laboratories, operating theatres, ICU’s, etc.) the units will be installed close to the patient or opposite the patient’s bed. Negative (infectious patients) or positive (immune compromised, operating theatres) pressure inside the room in relation to the adjacent area’s may be required.

MedicCleanAir® units can also be used as a protective measure against aspergillus outbreaks caused by renovation and construction works.

For every situation, MedicCleanAir® can offer you a solution. Consult the following advice or contact us directly.

See for examples

Airborne Hospital Infections

Information

Increasing air pollution combined with the rising number of patients with immune system deficiencies has become a serious problem within the Hospital Environment.

There is a huge price to pay for airborne infections, both in terms of human life and financial costs. Consequently there is a general need to ensure that the air in the hospital environment – in all parts of the facility – is of the highest possible quality.

Medically controlled air is the only reliable solution and this should be based on the most important requirement – it has to be thorough – all pollution must be eliminated.

There is no point in cleaning just a little.

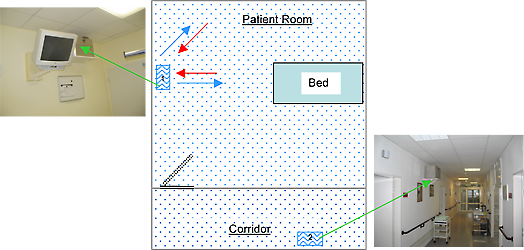

This drawing illustrates the importance of eliminating all contamination.

Air is a major 'transporter' of infections and airborne infections are neither limited to certain sources nor boundaries. There are a huge number of potential sources of infection ranging from outside air to defective ventilating systems, construction material and people be they staff, visitors or patients.

Important fact

An important fact is that the majority of airborne infections develop inside the hospital.

Installation of air purification unit PRO110

The unit is to be put on a shelf at minimum 2/3rd of the height of the wall. For immune compromised patients, the unit is installed opposite the bed, for infectious patients, the unit is installed next to the bed. Maintenance to be carried out between 12 and 18 months after installation. All MedicCleanAir® Units are equipped with an alarm that informs the client when the filter cartridge needs to be changed.

MedicCleanAir® Units are also installed outside the patient's rooms to clean sources of airborne infections in the surrounding areas like the entrance of the department and the corridor. (See also FAQ – Installation of MedicCleanAir® Mobile HEPA Units)

Isolation Rooms: the Medic Clean Air® – ISO Concept

Through our international contacts, we noted an increasing need for isolation rooms in hospitals.

The MedicCleanAir® – ISO Concept creates isolation rooms with pressure difference (positive or negative) + superior air quality in less than ½ day and for less than € 9.000.

MedicCleanAir® advice

Use air purification unit PRO110 + optional ISO120 – ISO210 or ISO520 (to create positive pressure inside the room) or COMBI (sterile and conditioned air combined)

What kind of isolation rooms

- Isolation rooms to protect immune compromised patients from infections (E.g. neonatology, BMT, Burn Units, oncology, etc.

CDC : P E Protective Environment - Isolation rooms to protect the environment from infectious patients (E.g. Tuberculosis, SARS, Avian Flu, Pox, …)

CDC : A I I Airborne Infection Isolation

Information

1. Protect the patient – PE – positive pressure rooms

Some patients are extremely vulnerable to infections for ex. Invasive Aspergillosis. The incidence of I.A. in various patient populations is considerable as proven by several medical studies.

Lung transplant, Allogenic Bone Marrow transplant, Acute Leukaemia etc. are major risk populations.

This risk of infections can be severely reduced when a patient has an environment with clean air and a protection, through positive pressure, against contamination entering from adjacent, connecting areas.

2. Protect the environment – AII – negative pressure rooms

There are an increasing number of patients that are a threat to their environment because of the infection they carry.

Patients infected with for instance SARS or – Multi Resistant – Tuberculosis have to be accommodated in isolation with all necessary precautions.

A considerable number of hospitals have either not sufficient allocations and/or these allocations do not offer the necessary conditions.

Plans to improve the present situation are often blocked by either the required budget and/or the implications of major reconstructions like closing down complete departments.

The MedicCleanAir®-ISO Concept offers an alternative that allows every hospital to fulfil its needs for professional isolation rooms. Negative or positive pressure can be created in each and every room within ½ day work.

The difference between air flow and pressure difference

Airflow is the direction of air.

In a negative pressure room, the direction of the air flow is from outside the room to the inside of the room.

In a positive pressure room, the direction of the air flow is from inside the room to the outside of the room.

The more air is extracted or supplied to the room, the stronger the air flow will be.

Pressure difference between a room and the adjacent area.

Pressure difference is created when air is being extracted (negative) or supplied (positive) to a very well sealed room. Whenever the room has an opening, grid, integrated A/C, bad sealed windows, bad sealed doors, the creation of pressure difference will be impossible. Even with large amounts of air (extraction or supply), the pressure difference will not be accomplished. Only air flow will increase.

Conclusion:

The amount of pressure difference (Pa-difference) depends of the sealing off the room itself. All openings must be sealed before pressure difference can be established.

When pressure difference is not obtained, it does not mean that the isolation room is not working properly. Namely, the air flow is correct and that is the main requirement.

Please contact MedicCleanAir® for a tailor made proposal.

ICU – Oncology – Neonatology – Transplants

Advice from MedicCleanAir®

Use air purification unit PRO110 + optional ISO120 - ISO210 or ISO520 (to create positive pressure inside the room) or COMBI (sterile and conditioned air combined).

Reference

University of Genoa – Hospital S. Croce e Carle, Cuneo – Italy

Bone Marrow Transplant (2002)

2 year tri-parametric study

Results and conclusions: MedicCleanAir® reduces CFU’s up to ZERO and no more infections occurred as from the use of MedicCleanAir® units.

For further information, see medical studies or contact us directly.

Operating Department – day surgery

Advice from MedicCleanAir®

Use air purification unit PRO110 + optional ISO120 – ISO210 or ISO520 (to create positive pressure inside the room) or COMBI (sterile and conditioned air combined)

Immediate Perfect Air Quality in the O.T. for a minimal budget and no (construction) efforts.

MedicCleanAir® can provide you with an operating theatre of class ISO 8, ISO 7 or even ISO 6 within 1 day installation time.

Reference

Scientific study – University of Liège – Sart Tilman – Hôpital de Bruyères – operating theatre – Results with MedicCleanAir® Units:

- Particle counts reduced from 8.297.495/m3 to 112.190/m3 (99% reduction)

- CFU counts reduced from 31 CFU to 0 CFU (100% efficiency result)

- The operating theatre was (without any other additional measures or changes other then MedicCleanAir®) re-classified to ISO 7.

For further information, see medical studies or contact us directly.

Tuberculosis, SARS, Avian Flu and Air Purification

Advice from MedicCleanAir®

Use air purification unit PRO110 + optional ISO120 – ISO210 or ISO520 (to create negative pressure inside the room)

Reference

University Hospital St. Pierre – Brussels & Pasteur Institute – Lille

The hospital has been appointed by the Belgian government to be the reference centre for Belgium in case of a pandemic.

After evaluation by the Pasteur Institute, MedicCleanAir® Units are installed in all isolation rooms (mainly for tuberculosis)

For further information, see medical studies or contact us directly.

Construction and renovations in hospitals

Can cause severe concentrations of aspergillus that may infect or even kill immune compromised patients.

Advice from MedicCleanAir®

MedicCleanAir®-PRO 110 Air Purification Unit + pré filters (= filters on the outside of the unit / air inlet of the unit)

Proven outcome: over 97% reduction in CFU concentrations

(Mahieu LM, De Dooy JJ, Van Laer FA, Jansens H, Ieven MM. - Journal of Hospital Infection 2000;45:191-197)

MRSA Patients in hospitals

Advice from MedicCleanAir®

Use air purification unit PRO110 + optional ISO120 – ISO210 or ISO520 (to create pressure difference)

Information

Although MRSA is (mainly) transferred through direct contact, it has been noted that MRSA particles are found at places / surfaces that have not been touched by people. Consequently, air must be the transporter for these concentrations.

By implementing MedicCleanAir® units, the incidence that patients are infected through contacting contaminated surfaces, is strongly reduced.

Additionally, most MRSA patients are immune compromised. With MedicCleanAir® units, the air quality inside the room is optimized and the patient is protected in the best way possible against other airborne acquired infections.

For further information see medical studies or contact us directly.

Emergency Departments – General safety for healthcare workers

The risk that hospital staff gets infected with i.e. Tuberculosis is higher in the general departments (non-isolation) than in special equipped departments (isolation rooms).

Examples of these general departments at high risk are i.e. emergency departments.

Advice from MedicCleanAir®

use MedicCleanAir®-PRO 110 units

Reference

University Hospital St. Pierre – Brussels, ZNA – Hospitals – Antwerp –, University Hospital – Ghent

For further information see medical studies / references or contact us directly.

Laboratories – IVF-Cytostatica-Pharmacy-Pathology

Advice from MedicCleanAir®

Use air purification unit PRO110 with special filter cartridge + optional ISO120 – ISO210 or ISO520 (to create pressure difference), or COMBI (sterile and conditioned air combined)

Formation, spread and inhalation of particles is a well known problem within laboratories.

Infectious aerosols can be divided into two groups:

- particle based (including droplets)

- toxic agents (chemical compounds or gases)

Our special made filter cartridges with considerable amounts of activated carbon reduce large concentrations of gas and particles within the lab environment.

Depending on the type of lab, one requires negative (cytostatic–pharmacy-pathology) or positive (IVF-lab) pressure.

MedicCleanAir® offers transformation of your laboratory to class ISO 8, ISO 7 or even ISO 6 within 1 day work.

Mobile Hospitals – MOD & Environmental Disasters

It is clear that in case of war, more casualties are to be treated than when there is no war. Biological and chemical agents make part thereof.

The same applies to environmental disasters such as earth quakes, flooding, eruptions, etc.

Mobile hospitals (tents or containers) are flexible and presently very well equipped, except for the air quality inside the high care areas.

Clean air and pressure difference (negative or positive) are also required and can easily be provided by our compact and mobile MedicCleanAir® units.

Advice from MedicCleanAir®

Use air purification unit PRO110 + optional ISO120 – ISO210 or ISO520 (to create positive pressure inside the room) or COMBI (sterile and conditioned air combined)

«With the recent outbreak of the deadly Corona virus, it is extremely important for hospitals with isolated infected patients to keep the air in their environment safe and clean. Here is a small appearance of one of our air purification systems reported in the Belgian press this week.»